The traditional professions in Lesvos reflect the particular socio-economic conditions prevalent from the 18th to the 20th century within a historical context of incessant and historic changes. As an island Lesvos in that period presented important development in the merchant marine and commerce. However, its special geomorphology contributed to the emergence of a complex society with a social organization that included activities, such as agricultural cultivation, livestock farming and small industrial business enterprises. Since the mid-19th century economic development, the introduction of new technologies and other factors have intensified the specialization of labor output. Thus, many urbanized settlements specialized in particular small industry activities, producing goods which served the need not only of their fellow locals or islanders, but were exported to other regions in Greece, Asia Minor and beyond. A few of these professions of the past are listed below starting from the 1850s until today. Some of them remain unchanged other have become obsolete and disappeared.

Traditional Professions

Δες όλα τα επαγγέλματα

Barbers were employed exclusively to tend the haircutting and shaving of men. Typically they picked up the craft as apprentices with experienced barbers. Their first customers were usually friends or relatives after attending seasoned barbers at work. The barber profession must have been especially popular in the 1960s as there were in Mytilini approximately 45 barber shops. Many barbers practiced their trade away from their shops as they offered their services to customers at the kafeneia. After the 1970s the barber’s profession was organized in two powerful guilds, the Barbers and the Handymen Unions; but this came to an end in 1975 with the establishment of one single unified trade union shop, the Barbers and Hairdressers Union. Barbers are now becoming obsolete as they seem to have been absorbed by hairdressers, both male and female.

On the island of Lesvos musicians were called “mousikandes” or “paikhnidiatores” (musical instruments were “paikhnidia” = toys). They usually performed in pairs (davul/zurna or davul/clarinet) or larger ensembles, such as fiddle, sandur, winds or other string instruments. Musical ensembles consist of family members, going on tour throughout the wider region, playing in weddings, engagements, festivals and shows at coffee houses. All villages had ensembles, but villages such as Agiasos, Plomari and environs, Skoutaros, Mantamados, Kapi, Aghia Paraskevi, Mesotopos and the vicinity of Gera stand out for their musical tradition.

The millers worked at their mills, a big building, equipped with two massive, wide stones rubbing against each other, operating either on wind power or running water, with attached storage spaces. Almost all Lesvian villages had their own windmill, especially at seaside villages with strong wind exposure or in the hinterland close to rivers or streams with strong currents there were watermills. Millers rarely were paid with money. They usually charged a commission equaling to 5 to 10% of the ground flour. Wheat cultivation was widespread in the 17th century, but then started to drop drastically. The millers are now mostly obsolete and industrial milling installations have taken their place as they are capable of mass-exporting. There is a plethora of abandoned windmills that the visitors always admire throughout the island. The windmill at Perama Gera, the watermills in the Ligona valley and the Kato Myloi are famous, while there is also a flour mill in Lisvori still in operation.

Stone carvers were craftsmen who chiseled out stones with the use of iron implements to give block form, amenable to be used in building residences and churches. Their trade required special dexterity and attention. Stone carvers processed stones mined in Lesvos, their favorite stone being the reddish Mistegná rock and stones imported from Asia Minor.

Farriers (horseshoe-makers, equine hoof carers) were indispensable in old times since all households had at least one hoofed pack animal (a donkey or a mule) to help out in the economic life of farmers and traders. All single-hoofed on the island had to be fitted with horseshoes at regular intervals since intensive labor and the rough mountainous terrain wore the equipment down rapidly. Horseshoes were hand-made of iron wrought on anvils, while craftsmen undertook to fit the horseshoes on the animal, a job requiring experience and skill. Horseshoe-makers usually were ironsmiths and/or self-styled veterinarians also spaying all kinds of animals.

The ouzo and raki makers were traditionally called “rakokazanades” or “rakitzides” (“kazani” being the popular term for the copper alambics or stills used in spirits distillation). The farmers brought the pomace to the distillers and he boiled it to produce pomace-alcohol (the “souma”), and this was handed over to the producers in clay containers. The souma was then mixed with anise to produce ouzo (or raki), and sometimes they added some Chios mastic. The distillers were numerous throughout the island and each town and village had quite a few rakokazanades, at a time when homemade ouzo was prevalent and unregulated.

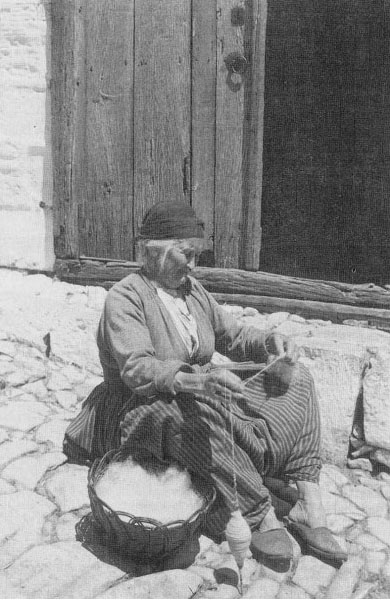

Fabric weaving was the primary woman’s occupation and it usually took place within the household. The loom was a standard for almost all households and girls under the guidance of their mothers or grandmothers wove all kinds of everyday fabric items, such as underwear, pillows, pillow cases, bed spreads, blankets, sheets, even their own dowry linen. The raw material going into weaving was sheep’s wool, locally grown cotton, flax, even silk cultivated on the island as late as the end of the 19th century. Spinning the yarn and fibers, carding and all loom work required a lot of work hours. For this reason almost all peasant women dealt with fiber spinning and textile making in the spring and the summer, when there was no work in olive picking and oil production in the fields. Traditional weaving still survives in some Lesvian villages, such as the peasant communities of Agiasos, Asomatos, Pigi, Lafiona, Agra, etc.

Besides repairing broken-down footwear, the cobblers in the past made shoes themselves. The cobbler’s shop was open from sunrise to sundown, with a workbench and shoe repair/making tools. He was stooped over his bench, working endless hours wearing the characteristic leather apron. At that shop he received orders from his customers. Those were times when people could not afford to buy new pairs of shoes every time they wore out. Thus, they had to go the cobbler’s for repairs, such as sewing up holes, gluing detached soles, replacing worn soles with new ones. This profession is almost gone now.

The local clay potter’s craft goes back five thousand years, as the prehistoric Thermi excavation findings show. Potters on this island are known in the local parlance as “tsoukalades” or “koumarades”, i.e. makers of clay vessels (“tsoukalia” or “koumaria”). This craft was handed down from father to son to grandson and so on, so it was a matter of inheritance to posterity. Major pottery centers in Lesvos have always been Mantamados and its environs (Aspropotamos, Aghios Stephanos, etc.) and Agiasos. However, in the 18th and 19th centuries more villages joined the pottery-making trade such as the villages of the Gera region (Palaiokipos, Perama etc) producing the popular “gerayiotika” jars, Filia and Skalohori, at that time called Tsoukalohori with its significant Muslim community and immense production of clay vessels. Each locale specialized in its own type of clay vessels, depending on know-how, heritage and composition of clay raw material. There were clay pots for cooking, cups, glasses, dishes (“testa”) for the dining table. “Koumaria” and “tsirokoumara”, decanters, olive oil or cheese storage jars or fresh water carriage (“koutrouvia”), large jars for olive oil and clay roof tiles, bricks, censers (bee smokers for bee farming), clay flutes and dumbeks (percussive instruments) for occasions of merriment. Clay vessels were sometimes decorated with floral motifs and representations from everyday Lesvian life.

Tanning is the art of processing leather goods. The small tanning industry developed on Lesvos in the end of the 19th century using as raw materials leather and hides, locally procured or imported from other regions in Greece, South America or Africa. The greatest tanning factories in Lesvos were in Mytilini, in the Tambakika location in the North Ports, in Plomari and Perama in the Gera vicinity, where one of the biggest tanneries in the Balkan region was built in the end of the 19th century. The tanneries were always built close to the shore so they could easily get water and salt that were indispensable for leather processing. In 1913 twenty major tanneries were in operation throughout Lesvos, reduced to 14 by 1921. This diminishing course continued in the post-WWII years until 1990, the year the last tannery ceased operation in Perama of Gera.

Wood carving was very much developed in Lesvos, especially in the making of trunks. Trunks or storage boxes were made from local wood, sometimes with no decorations, some had wood-carved decorations with traditional folk motifs, such as cypress trees, eagles, flowers on the front side. Some craftsmen built dining furniture sets, recliner chairs, bedroom drawer chests for newlyweds, and ornate mirrors for the roomy reception spaces in upper-class mansions. Lesvian wood carvers also constructed altar pieces for churches, bishop thrones or artful Holy Week epitaphioi. There are still quite a few Lesvian wood carvers especially in the villages of Agiasos, Asomatos and Eftalou.

Cultivation of olives has always been and still remains a significant trade in the agricultural life of Lesvos. Around the end of the 19th century the first steam-powered olive oil presses started to be built, in which the olive fruit processing was done by olive oil mills powered either by menial power or with beasts of burden. The olive oil presses belonged to one or more owners who hired a certain number of laborers. The horse pushed the capstan (“volia”) for the milling of the olive fruit and the remaining work was completed menially, while the manual olive processes operated with help of a bolt (“adrakhti”). Olive oil pressers were organized in powerful and popular guilds in all villages and towns of Lesvos. Until 1912 the Ottomans taxed olive producers in kind under poll tax systems (one-tenth collection) and their production output was inspected by a tax collector (“mamouris”). The first steam-powered olive mills were built in the beginning of the 20th century. Steam energy made possible the crushing of increased quantities of olives and the expedited production of good-quality olive oil. The olive mills were built with investments by Lesvian tradesmen and landowners and they were specially lucrative enterprises. Since the 1920s many cooperative olive oil presses have been established. Steam-powered olive presses decreased dramatically in the post-war years, due to the decline in agricultural economy. After the 1970s all steam-powered facilities were being gradually replaced by modern electric-powered centrifugal machines requiring very few laborers.

In Lesvos the basket weaving craft was strongly and traditionally embedded in Asomatos and Gera while many family basket weaving businesses could be found all over Lesvos, such as the village of Skoutaros. Basket weavers wove their baskets using chaste tree (“lygaria”) stems that grew near rivers and streams. The sizes and the types of baskets varied depending on their function and use. There were baskets for carriage of fruit, the washing of clothes and artful intricately woven baskets for festive moments. A basic tool in basket weaving is the wooden splitter, which tore through the reeds and the thread cutter used to drill holes to fix handles.